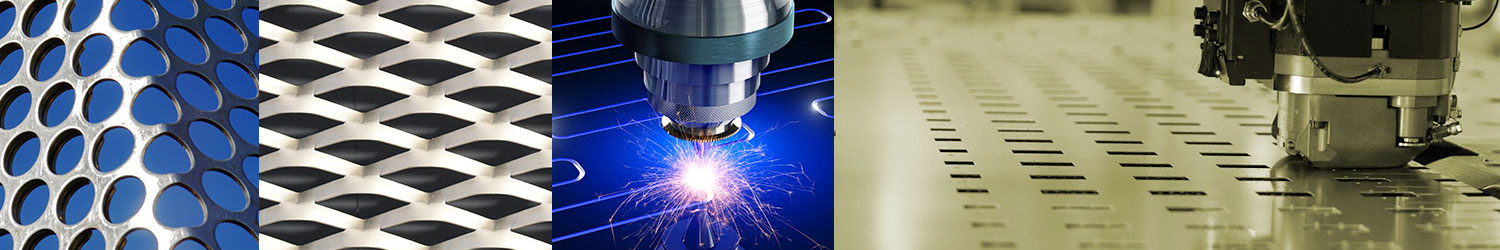

Laser Cutting

Laser cutting is a process that uses an intense laser beam to rapidly cut nearly any shape in sheet material. Parts remain flat because the heat distortion is minimal. The edges are precise and smooth, and the finished parts are ready for assembly without requiring additional work. We provide laser cutting services using two high speed Trumpf lasers to ensure fast turnaround and availability.

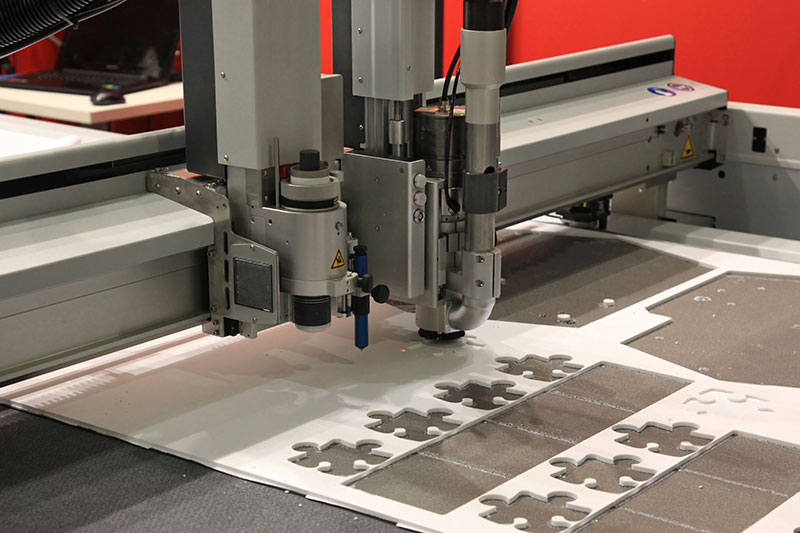

Waterjet Cutting

Waterjet cutting is a technique using very high-pressure water, often combined with abrasives, to cut both hard and soft materials. Waterjet cutting is often used during fabrication of machine parts, and is the preferred method when the materials being cut are sensitive to high temperatures. We provide cutting services, using a modern Flow Mach 3 waterjet, on a wide variety of materials.

CNC Bending

CNC bending is a process where sheet metal is bent to an angle when placed between the V shaped punch and die and subjected to pressure. CNC bending is suitable for processing sheet metal designs with one or more bends. No special tooling is required for CNC bending except for intricate designs and special bend patterns.

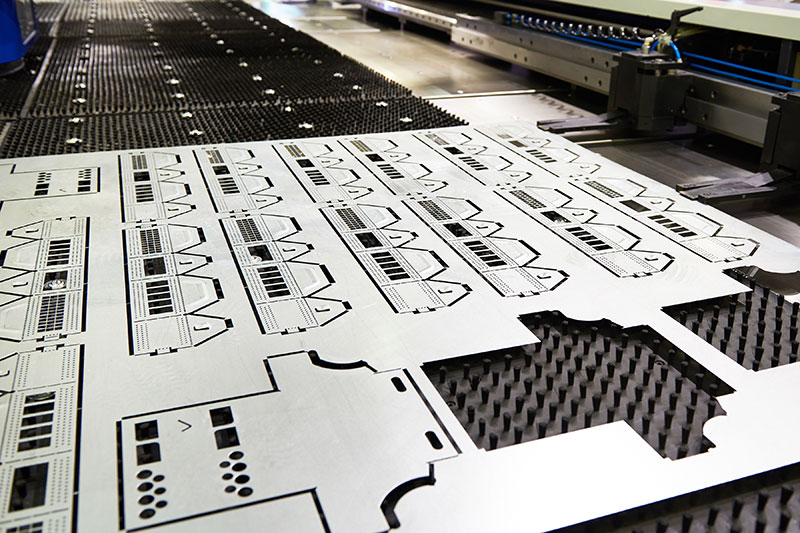

CNC Punching

CNC punching is a computer-controlled process that can punch complex shapes by using a combination of single hits and overlapping geometries. Special software can help to maximize the yield from a given sheet metal panel. This process is ideal for generating quality, custom-made sheet metal fabrications in high volumes at low cost.

Other Services

In addition to our cutting, bending and punching services, GDMPI also provides high speed metal stamping, welding, rolling, forming, and powder coating services. We are able and willing to take on difficult jobs that are beyond the capability of less experienced companies. Our innovative staff and engineers have developed special techniques and even built custom machines for many special projects and unique architectural details. Tell us what you imagine, and let us show you how it can be done!

Custom Fabrication

Metal Stamping

Welding