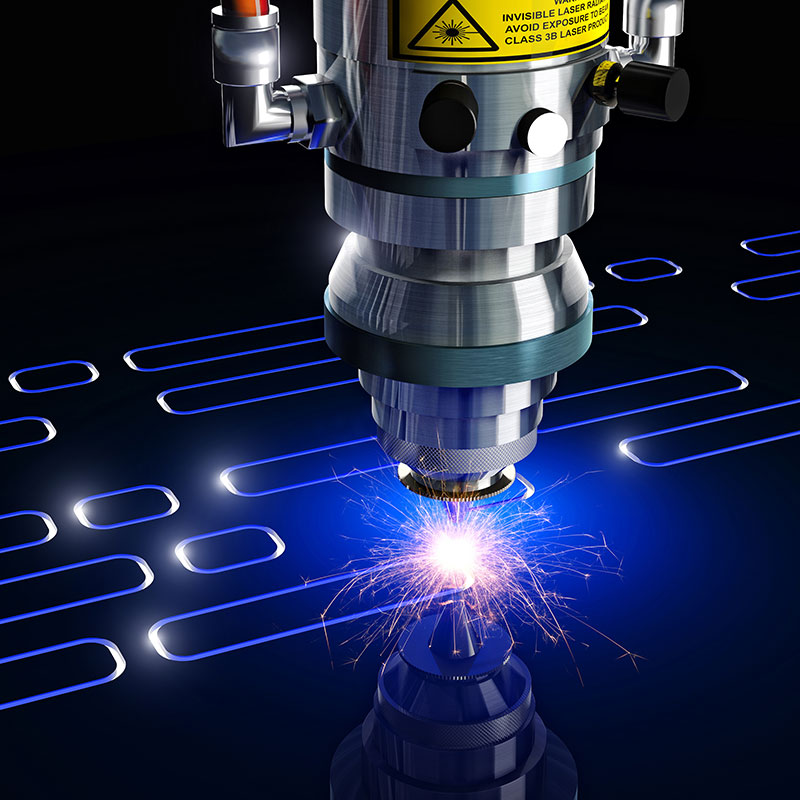

Lasers have become one of the most useful tools in metal cutting. The most recent technological development in laser cutting is the fiber laser. Unlike the classical CO2 laser, a fiber laser generates the laser beam within a special optical fiber. This provides unique capabilities, and certain advantages, over the CO2 laser:

- Since the light is generated within an optical fiber, it can be easily conveyed to a moving head without complex optics

- Because the fiber can have long active gain regions, very high power can be generated.

- The wave guiding properties of a fiber reduce thermal distortion of the optical path.

- Fiber lasers are more compact, have very high temperature and vibrational stability.

- High peak power and nanosecond pulses enable better marking and engraving performance.

GDMPI operates both traditional and fiber laser equipment. The choice of which method is best for a given application depends upon the type and thickness of the material and the particular job characteristics.